Glove Gauge And Its Impact On The Use Of Cut-Resistant Gloves

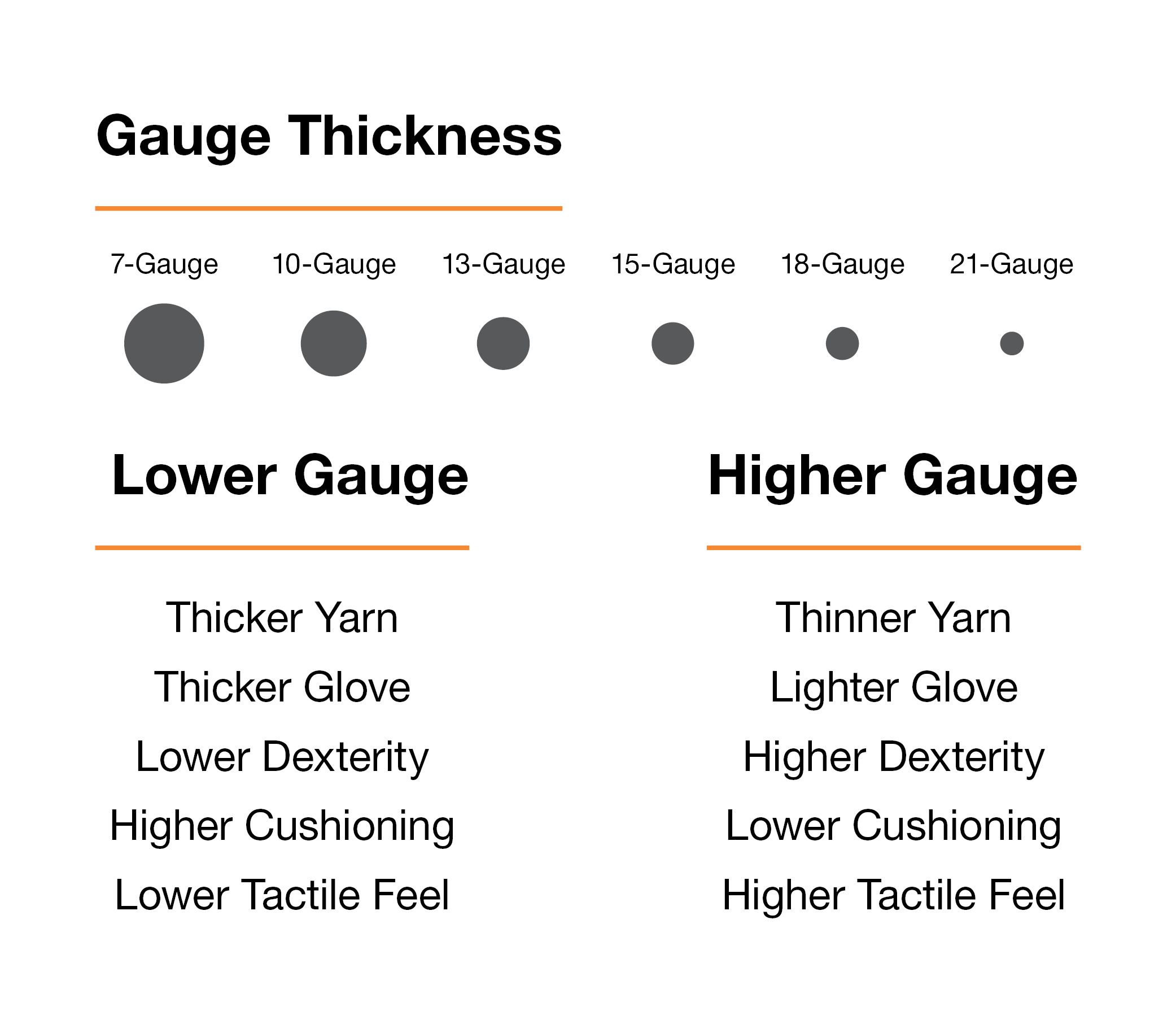

Gauge is defined as the number of stitches included in each inch of yarn. As the number of stitches increase, so does the gauge. Note: Although gauge refers to the yarn, it’s common to hear it called glove gauge. This has the same meaning and is a shorthand way of referring to the thickness or thinness of a glove.

Below is a quick overview of glove gauges, including their thickness and dexterity level, and how they impact a glove’s feel and performance in tasks that involve cut hazards.

English

English 中文

中文 Deutsch

Deutsch Español

Español Português

Português 日本語

日本語 русский

русский